You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

First time a Tornado in Barcelona

- Thread starter oriol

- Start date

Looking good, keep on trucking.

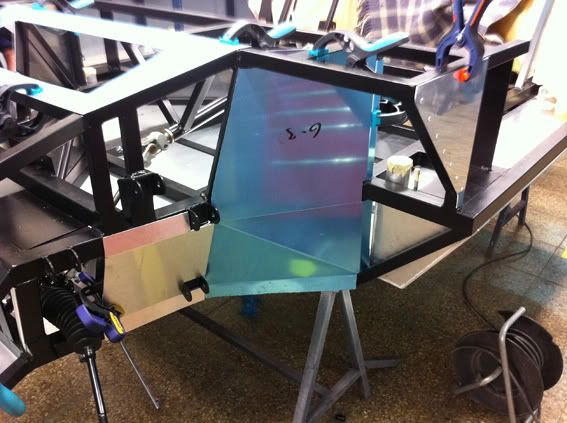

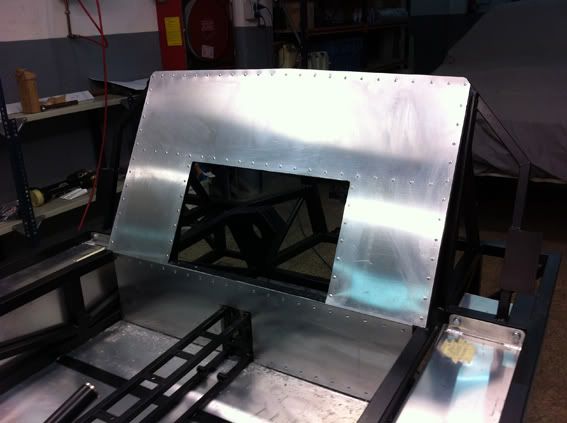

It's straight, no bend below the window.

I think Tornado modified the chassis to accommodate the Coyote engine, so it doesn't need the fold in the rear panel unlike ours.

Your build is looking good.

Your build is looking good.

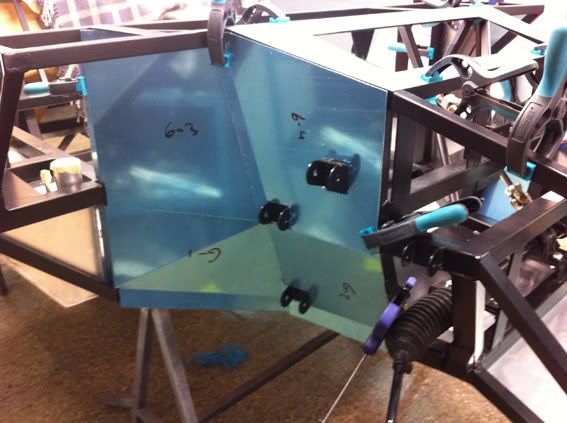

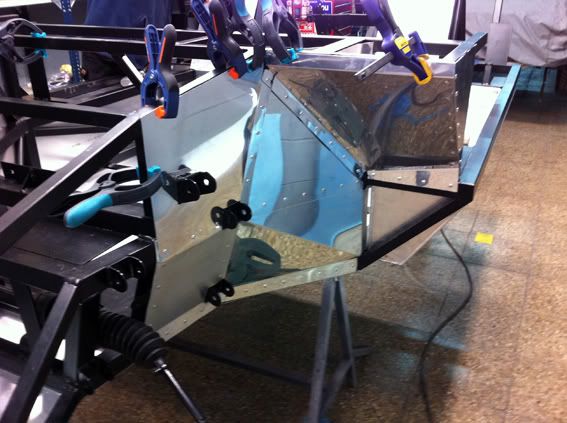

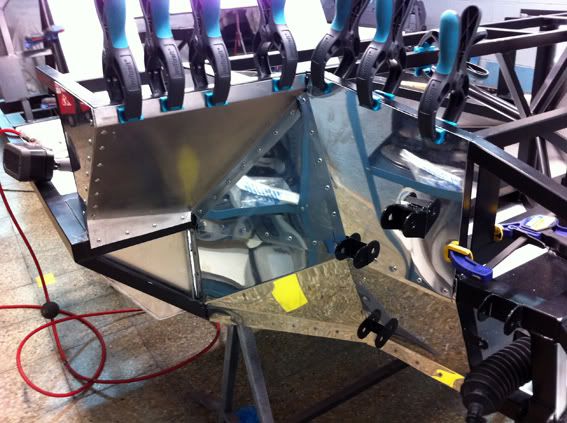

There is no bend at the top of the rear bulkhead as this is a Coyote powered car.

More space is required higer up to clear the quad cam heads.

Also no bump is needed in the rear bulkhead to clear the water pump pulley so its just a flat panel for the engine cover in the bulkhead.

The bulkhead is different as is the engine bay.

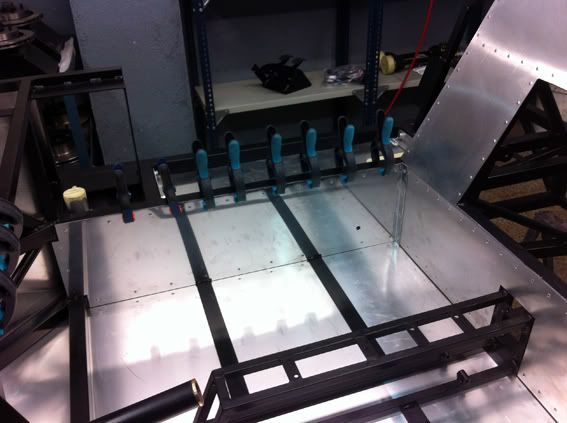

The braces are made to bolt in so that they can be fitted after the panelling is completed to make the job easier and neater.

You are making fast progress now Oriol.

Thanks

Andy

More space is required higer up to clear the quad cam heads.

Also no bump is needed in the rear bulkhead to clear the water pump pulley so its just a flat panel for the engine cover in the bulkhead.

The bulkhead is different as is the engine bay.

The braces are made to bolt in so that they can be fitted after the panelling is completed to make the job easier and neater.

You are making fast progress now Oriol.

Thanks

Andy

Wow....I need a napkin now :thumbsup:

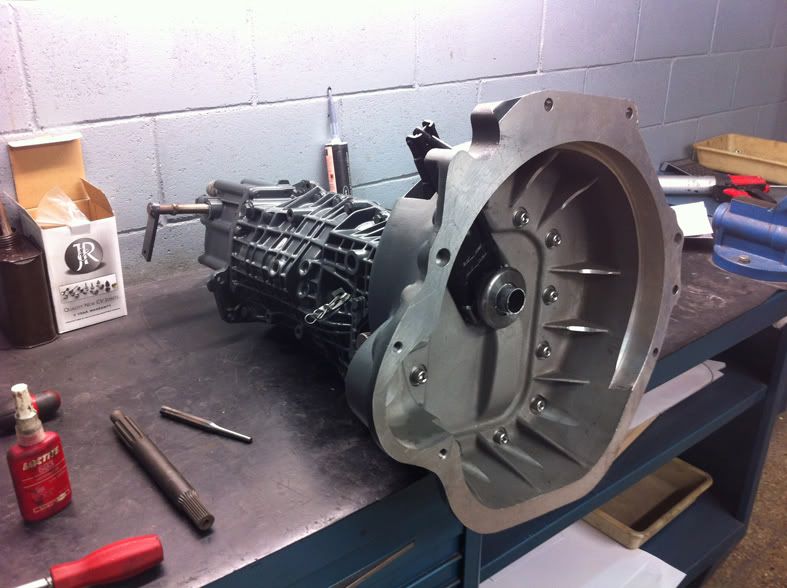

Love the color on the transaxle.

Love the color on the transaxle.

Similar threads

- Replies

- 0

- Views

- 167

- Replies

- 19

- Views

- 5K