You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

David G 69 Gulf SPF build begins.

- Thread starter 68Rcodeman

- Start date

David Garton

Supporter

So I have been accumulating needed parts to start the install. I now have the clutch and bellhousing kit with 141 tooth flywheel and external slave cylinder. Then while the engine is on the stand I went through all the loose brackets furnished with the car without any assembly manual. Worked on getting the AC compressor bracket mounted to the right side of the engine. With the Gurney heads the mounting holes are different and the Motorsports block had the boss casted below the head but not drilled or tapped. I was able to get two in the head and drilled and tapped 3/8 hole in the boss under the head and add a third mounting bolt for the AC bracket.

Attachments

Last edited:

David Garton

Supporter

I removed the long nose waterpump and installed the shorty pump from Ford Motorsports . Ordered the double pulley kit from CVF billet pulleys. When ordering they ask factory or aftermarket balancer. Well I said factory and the Crank pulley was an inch short from lining up with the water pump pulley. No biggie because when I called technology they had the adapter in stock and sent it no charge. I was so happy I went back online and ordered their double grooved alternator pulley. After going cross eyed over trying to figure out the loose brackets and pulleys with bearings and C-clips to retain them I have my alternator and AC compressor with all pulleys lining up and the tensioner adjusting tension on both belts and a very good wrap around the compressor pulleys and get to use both of the same belts. Thus leaving me plenty of room on the left side of the engine for the water pump hose and the thermostat housing hose that drops down the same side. All pictures are for fitment and alignment purposes and I am taking it apart and blasting the brackets and powder coating them one color.

Attachments

-

20240223_165544.jpg231.2 KB · Views: 220

20240223_165544.jpg231.2 KB · Views: 220 -

20240218_095544.jpg308.5 KB · Views: 217

20240218_095544.jpg308.5 KB · Views: 217 -

20240223_133607.jpg653.3 KB · Views: 207

20240223_133607.jpg653.3 KB · Views: 207 -

20240223_140055.jpg410.1 KB · Views: 201

20240223_140055.jpg410.1 KB · Views: 201 -

20240224_165351.jpg424.1 KB · Views: 195

20240224_165351.jpg424.1 KB · Views: 195 -

20240224_165119.jpg556 KB · Views: 190

20240224_165119.jpg556 KB · Views: 190 -

20240224_175151.jpg393.6 KB · Views: 175

20240224_175151.jpg393.6 KB · Views: 175 -

20240224_175205.jpg581.6 KB · Views: 180

20240224_175205.jpg581.6 KB · Views: 180 -

20240224_175225.jpg494.3 KB · Views: 172

20240224_175225.jpg494.3 KB · Views: 172 -

20240224_175307.jpg422.6 KB · Views: 196

20240224_175307.jpg422.6 KB · Views: 196

Last edited:

David Garton

Supporter

Now that the front of the engine is figured out I will remove the engine from the stand and mount the flywheel and the the bellhousing and zero runout the bellhousing then install the clutch assembly. I want to send the bundle of snakes out for jet hot coating but think I need to test fit it first and make sure they clear the upper crossmember first.

Attachments

-

20240224_175317.jpg417 KB · Views: 183

20240224_175317.jpg417 KB · Views: 183 -

20240223_111656.jpg660.4 KB · Views: 186

20240223_111656.jpg660.4 KB · Views: 186 -

20240223_111633.jpg728.9 KB · Views: 170

20240223_111633.jpg728.9 KB · Views: 170 -

20240223_111622.jpg611.2 KB · Views: 162

20240223_111622.jpg611.2 KB · Views: 162 -

20240223_111617.jpg505.8 KB · Views: 157

20240223_111617.jpg505.8 KB · Views: 157 -

20240223_111559.jpg347.6 KB · Views: 158

20240223_111559.jpg347.6 KB · Views: 158 -

20240223_111611.jpg673.4 KB · Views: 153

20240223_111611.jpg673.4 KB · Views: 153 -

20240223_111604.jpg728 KB · Views: 145

20240223_111604.jpg728 KB · Views: 145 -

20240223_111636.jpg625 KB · Views: 149

20240223_111636.jpg625 KB · Views: 149 -

20240223_111613.jpg431.1 KB · Views: 235

20240223_111613.jpg431.1 KB · Views: 235

Is it crucial to zero runout the SAFIR bell housing? If yes, how does one do that? thanks

David Garton

Supporter

Lee It is very important and can make for ease of shifting and longevity of input bearing and other clutch and trans components. Just a good practice to check it. There are offset dowls that you install in the block to move the bellhousing. Not just Safir bellhousings but all bellhousings. Here is a link to help you understand the way it is done.Is it crucial to zero runout the SAFIR bell housing? If yes, how does one do that? thanks

Interesting video. But I thought the runout was measured at the face of the bell housing and and how parallel it is to the flywheel. This guy is measuring the inner bore of the bellhousing. Not really following how it applies to the Safir bell. thanks

David Garton

Supporter

Measured both. First measurement is most important! If it's not centered it will move the input shaft around and cause shifting issues and pre-mature failures.Interesting video. But I thought the runout was measured at the face of the bell housing and and how parallel it is to the flywheel. This guy is measuring the inner bore of the bellhousing. Not really following how it applies to the Safir bell. thanks

Here’s a good thread from BryanF’s build.

Regards Brian

Quaife bellhousing on Ford block

The Ford dowels are 0.5" but the holes in the Quaife E62G1121 bellhousing are about 0.46". Quaife advised against enlarging these holes since one of them is so close to the dowel hole for the Chevy block. How to solve this problem?

www.gt40s.com

Regards Brian

David Garton

Supporter

David Garton

Supporter

Joe, Thank you. I would say they are 1/8 to 3/16.What are your panel gaps set at? Those look great!

David Garton

Supporter

David Garton

Supporter

And I was so proud of my belt routing but alternator to high and had to remove to set engine in the car. Once in place I'm going to try with single pulley and see if it fits. Closer then I was when starting on Saturday.

Attachments

-

20240303_223707.jpg680.3 KB · Views: 232

20240303_223707.jpg680.3 KB · Views: 232 -

20240304_081128.jpg300.6 KB · Views: 211

20240304_081128.jpg300.6 KB · Views: 211 -

20240304_080801.jpg279.4 KB · Views: 221

20240304_080801.jpg279.4 KB · Views: 221 -

20240304_081154.jpg370.2 KB · Views: 192

20240304_081154.jpg370.2 KB · Views: 192 -

20240304_081142.jpg331.4 KB · Views: 196

20240304_081142.jpg331.4 KB · Views: 196 -

20240304_081212.jpg296.2 KB · Views: 208

20240304_081212.jpg296.2 KB · Views: 208 -

20240304_142150.jpg445.9 KB · Views: 214

20240304_142150.jpg445.9 KB · Views: 214 -

20240304_142210.jpg520.4 KB · Views: 221

20240304_142210.jpg520.4 KB · Views: 221 -

20240304_142143.jpg504.7 KB · Views: 209

20240304_142143.jpg504.7 KB · Views: 209 -

20240304_142203.jpg423.6 KB · Views: 212

20240304_142203.jpg423.6 KB · Views: 212

David Garton

Supporter

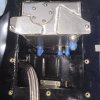

Well the test fitting was good for info. I had to machine .400 off the bottom rear perches that mount to the front of the lower crossmember. This will alow for moving the engine back a bit as the distributor cap was very close to the back of the cockpit. Today I test fit the transmission to the bellhousing without the clutch and made sure I had my pilot bearing set deep enough in the crank. Then the fun began for you dual disc clutch guys going together make sure you have an extra complete input shaft so you can have both disc splines in line. I put studs in the two 3/8 top of the Trans. This is a must if you ever want to pull the Trans without taking the engine and Trans out as one. My bellhousing has inspection covers at top and bottom so it was easy to add lock nuts to the top studs. Trans in and out of back of engine four or five times until I was satisfied with the throwout bearing to fork play. All the shims out from behind the throwout bearing and still had to machine the spacer that the bearing pressed on. All conected and very satisfied with today's progress.

Attachments

-

20240323_104606.jpg482.7 KB · Views: 168

20240323_104606.jpg482.7 KB · Views: 168 -

20240323_104901.jpg422.8 KB · Views: 171

20240323_104901.jpg422.8 KB · Views: 171 -

20240323_134555.jpg216.6 KB · Views: 165

20240323_134555.jpg216.6 KB · Views: 165 -

20240323_134848.jpg149.6 KB · Views: 156

20240323_134848.jpg149.6 KB · Views: 156 -

20240323_204508.jpg246.9 KB · Views: 159

20240323_204508.jpg246.9 KB · Views: 159 -

20240323_204517.jpg387.3 KB · Views: 159

20240323_204517.jpg387.3 KB · Views: 159 -

20240323_213758.jpg253.7 KB · Views: 152

20240323_213758.jpg253.7 KB · Views: 152 -

20240323_213613.jpg348.6 KB · Views: 158

20240323_213613.jpg348.6 KB · Views: 158 -

20240323_214308.jpg694.3 KB · Views: 166

20240323_214308.jpg694.3 KB · Views: 166 -

20240323_213926.jpg194.7 KB · Views: 174

20240323_213926.jpg194.7 KB · Views: 174

David Garton

Supporter

Been a while but Motor and Trans is installed and lower bellhousing mounts lined up and bolted to the crossmember. I had to replace the distributor with a shorter height unit with a small cap instead of the wide cap. I was able to make a good mounting system low on the left side for the alternator and keep my double pulley set up. Two of same belts and runs all the pulleys. Found some cool old school NOS ground straps.

Last edited:

David Garton

Supporter

Next was working on a Swirl pot that fits in the left side box as that's where the pumps will mount on firewall. Both tanks will run into the 1/4 way up point with one of the pumps pulling from lowest point of left tank and feeding the Swirl pot as the second pump pulls from the lowest point of the Swirl pot. Moving the oil cooler back by the side of Trans with remote oil filter so I can make air boxes above the fuel box and battery box to duct air to the rear brakes.

Attachments

-

imagejpeg_0(12).jpg210.7 KB · Views: 141

imagejpeg_0(12).jpg210.7 KB · Views: 141 -

KIMG3040.JPG199.7 KB · Views: 128

KIMG3040.JPG199.7 KB · Views: 128 -

imagejpeg_0(13).jpg214 KB · Views: 128

imagejpeg_0(13).jpg214 KB · Views: 128 -

Resized_20240408_215159_1712627539412.jpeg967.1 KB · Views: 119

Resized_20240408_215159_1712627539412.jpeg967.1 KB · Views: 119 -

20240615_085004.jpg666.8 KB · Views: 126

20240615_085004.jpg666.8 KB · Views: 126 -

Resized_20240406_185852_1712518969938.jpeg930.4 KB · Views: 124

Resized_20240406_185852_1712518969938.jpeg930.4 KB · Views: 124 -

20240701_215310.jpg289 KB · Views: 117

20240701_215310.jpg289 KB · Views: 117 -

20240701_215357.jpg257 KB · Views: 116

20240701_215357.jpg257 KB · Views: 116 -

20240701_215333.jpg267.8 KB · Views: 116

20240701_215333.jpg267.8 KB · Views: 116 -

20240701_215315.jpg193.8 KB · Views: 122

20240701_215315.jpg193.8 KB · Views: 122

David Garton

Supporter

I had a neat piece of the puzzle show up almost a year to the date of the delivery. And I plan on registering it as a 1969 so I stumbled across this fitting 69 Florida license plate. My chassis number is P1176 . 50 year Anniversary of P1075.

Attachments

David - not exactly following your routing. Is the right tank connected to the left via the Cross-over line?

David Garton

Supporter

Lee. Yes sir with a number 12 stainless steel hose. Removed at left tank where the swirl pot is being added and connecting right tank to lower swirl pot and straight shot from left tank to lower swirl pot. I have your mount part numbers for you.David - not exactly following your routing. Is the right tank connected to the left via the Cross-over line?

Similar threads

- Replies

- 22

- Views

- 5K

- Replies

- 50

- Views

- 14K