- Forums

- GT40 Replica Manufacturers' Corner

- RCR Forum - RCR40/SLC/917/Superlite Aero

- The SLC Clubhouse

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SLC 24 Howard Jones

- Thread starter Howard Jones

- Start date

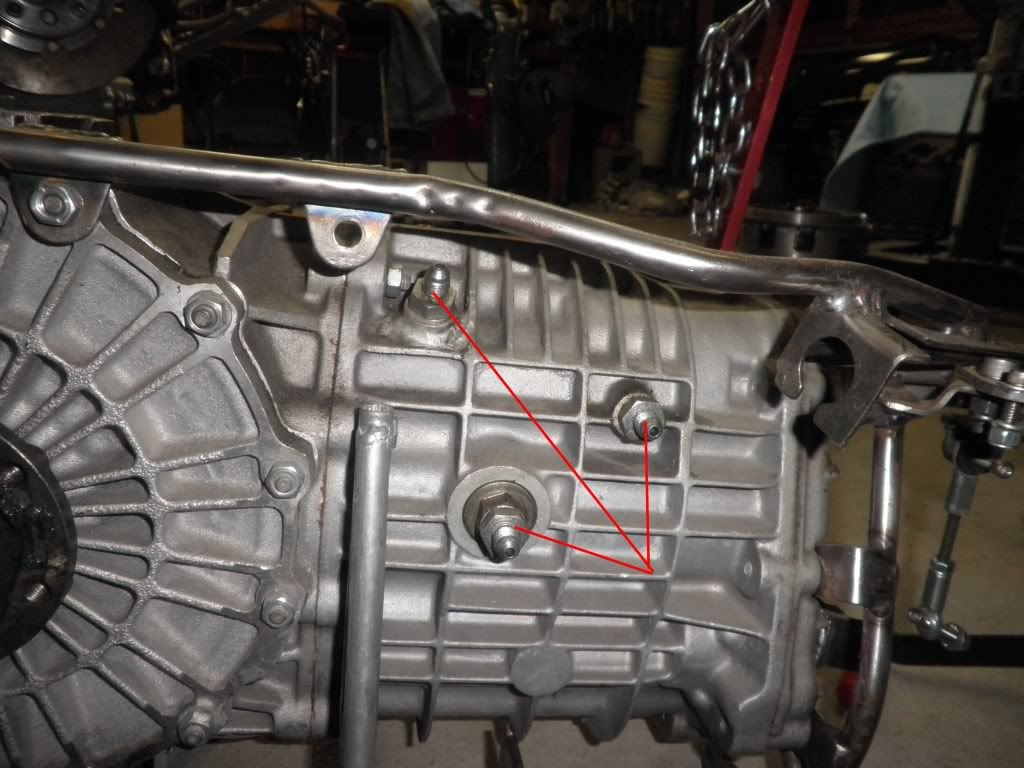

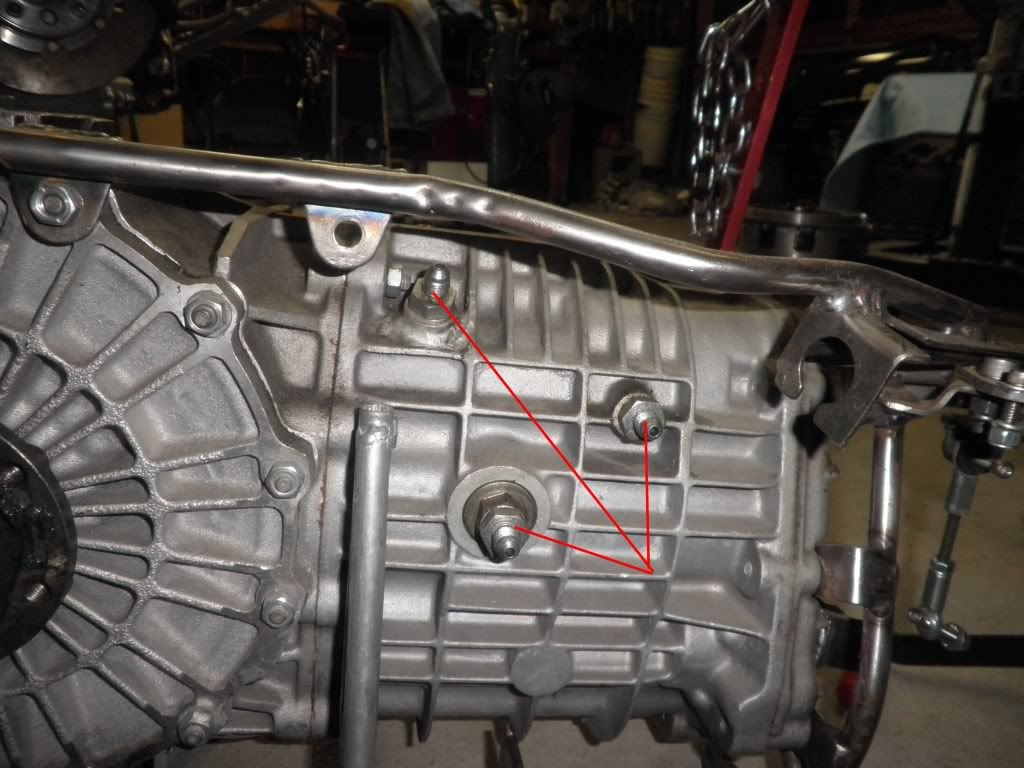

Here are some of the ideas I kicked around before going the route I did. You can use almost any of the nut/bolts on the side of the trans to construct a mount. The loads should be handled fairly easily.This is one on a G50 in a DRB which is different but you get the idea.

Here is a top hanging arrangement.

One more

And of course mine. I fabricated it out of some tubular product that I found at Home Depot. Bent it to shape, added the flanges, and triangulated it to the frame. Once done I ceramic coated them.

These are all 40s, but you should be able to run with it for your purposes. If you are using cable shift or even rod(s), it can serve as a support piece as well.

Bill

Here is a top hanging arrangement.

One more

And of course mine. I fabricated it out of some tubular product that I found at Home Depot. Bent it to shape, added the flanges, and triangulated it to the frame. Once done I ceramic coated them.

These are all 40s, but you should be able to run with it for your purposes. If you are using cable shift or even rod(s), it can serve as a support piece as well.

Bill

Howard Jones

Supporter

I made a couple of changes to the fuel lines. I didn't like the unsupported hose and as it turns out it was a perfect fit for carb line. Hard lines are better where they can be used anyway. They don't get old and need replacing.

This is a final final for the fuel system. Count it complete for now until I get a carb.

This is a final final for the fuel system. Count it complete for now until I get a carb.

Attachments

Very nice!

Going back a few posts, when we're talking about transaxle oil coolers, what forces the need for one - is it hp/torque that generates excess heat, or how the tranny is used (e.g., frequent high rpm shifts)? Or something else?

Current plans are shooting for around 850hp, but I have no intention on beating on it ..... running out of places where I could put the cooler .... however, since this is one of those things that would be so much easier if I didn't install it, something tells me I'm going to have to install it, heh!

Going back a few posts, when we're talking about transaxle oil coolers, what forces the need for one - is it hp/torque that generates excess heat, or how the tranny is used (e.g., frequent high rpm shifts)? Or something else?

Current plans are shooting for around 850hp, but I have no intention on beating on it ..... running out of places where I could put the cooler .... however, since this is one of those things that would be so much easier if I didn't install it, something tells me I'm going to have to install it, heh!

Howard Jones

Supporter

I think that the basic idea is that there are going to frictional losses of HP in the gearbox. Most people state this as a percentage of the power applied to it. Power equals heat. More power, in you case, nearly three times the power I am familiar with, will result in the gearbox getting hotter.

Now for shorter periods of time and relatively low power, like my track day sessions where 30 mins is a long one and I have 300hp at the wheels, the oil seams to remain within reasonable limits. I have seen a max of 170F, very hot day and a long run of 25 mins. BUT and this is a BIG but the harder you run it, well... we are back to, more power over a longer period of time will result in heat buildup in the GB oil. Anyway really short periods like one good blast away from a streetlight shouldn't effect GB oil temp. If you can't reject the heat then long runs at high power outputs will continue to heat the oil until it fails. When the oil fails the gears won't last more than a few seconds.

And that's the real issue. As the oil heats up it will get to a point where is burns. I would get real concerned if the GB oil got any hotter than 190F degrees. (somebody who really knows chime in right here).

Some things to consider are oil type, limited slips, very high grip tires (slicks), and airflow over the GB itself among others. As far as limited slips go the ones that have a friction system will generate the most heat (alot) and the Quaife types quite a lot less. Also spinning the tires will heat things up real quick.

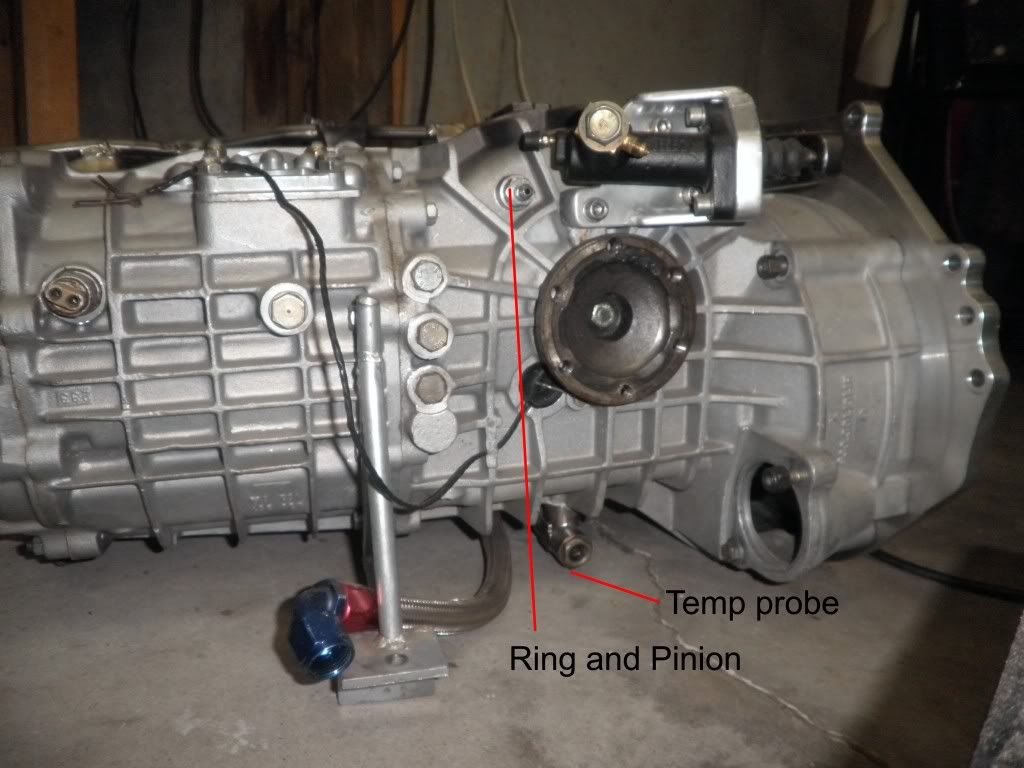

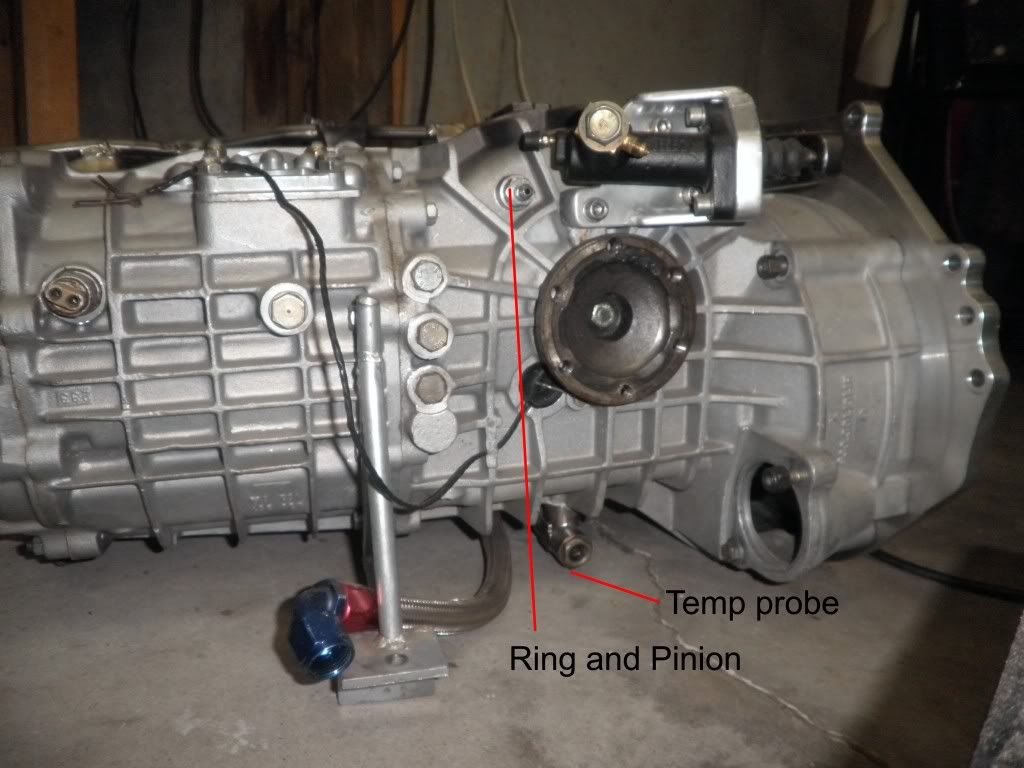

I intend to install a temp sensor and gauge in the G50 I have and go from there. If I see temp much above 170F I ma going to put a cooler in it with a pump and return the oil to 5th gear and the R&P. My box is already plumbed for this.

YOU however are in a place far beyond my planned 450HP. I would install a temp sensor and gauge and watch it very closely. You might need a pump no matter what you do. I would call a couple of GB vendors and ask your questions.

Don't save the few hundred it would take to put a cooler on it and FU a expensive GB. I don't know what you are thinking for a GB but forget anything cheap at those power levels. A Audi for example should last as long as the right foot can get to the floor the first time. You will find you are talking in the range of $15K to put together a power train to properly suit that much power.

You should ask this question on the GB page. You will get a lot of really good information.

Now for shorter periods of time and relatively low power, like my track day sessions where 30 mins is a long one and I have 300hp at the wheels, the oil seams to remain within reasonable limits. I have seen a max of 170F, very hot day and a long run of 25 mins. BUT and this is a BIG but the harder you run it, well... we are back to, more power over a longer period of time will result in heat buildup in the GB oil. Anyway really short periods like one good blast away from a streetlight shouldn't effect GB oil temp. If you can't reject the heat then long runs at high power outputs will continue to heat the oil until it fails. When the oil fails the gears won't last more than a few seconds.

And that's the real issue. As the oil heats up it will get to a point where is burns. I would get real concerned if the GB oil got any hotter than 190F degrees. (somebody who really knows chime in right here).

Some things to consider are oil type, limited slips, very high grip tires (slicks), and airflow over the GB itself among others. As far as limited slips go the ones that have a friction system will generate the most heat (alot) and the Quaife types quite a lot less. Also spinning the tires will heat things up real quick.

I intend to install a temp sensor and gauge in the G50 I have and go from there. If I see temp much above 170F I ma going to put a cooler in it with a pump and return the oil to 5th gear and the R&P. My box is already plumbed for this.

YOU however are in a place far beyond my planned 450HP. I would install a temp sensor and gauge and watch it very closely. You might need a pump no matter what you do. I would call a couple of GB vendors and ask your questions.

Don't save the few hundred it would take to put a cooler on it and FU a expensive GB. I don't know what you are thinking for a GB but forget anything cheap at those power levels. A Audi for example should last as long as the right foot can get to the floor the first time. You will find you are talking in the range of $15K to put together a power train to properly suit that much power.

You should ask this question on the GB page. You will get a lot of really good information.

Last edited:

Ouch....but true..:lol:

Howard Jones

Supporter

I would be very concerned running a standard "stock assembly standards and parts" Ricardo, or anything else for that matter in a road race application at those huge power settings. I find it hard to believe that any stock road car GB would live long at 1000HP.

I guess we will see. Eitherway that baby is going to get HOT if he runs it hard for much beyond 20 min.

Do Ricardos have LSD's in them? If so what type?

I guess we will see. Eitherway that baby is going to get HOT if he runs it hard for much beyond 20 min.

Do Ricardos have LSD's in them? If so what type?

According to my sources in the Porsche camp, a cooler is not needed except in the cars that do endurance runs, and then some don't then either. You will be running approximately 90 wgt. oil in the trans.

Some have internal spray bars to help out with the lubrication if the splash isn't sufficient. Remember some of us have inverted trans, so the splash is a little different. I have a cooler for my 40, but I approached the cooler option in that I already had an oil cooler on the left side and I had an open bay on the other side of the rear clip with nothing in it. So I evened things out with another matching cooler. The bling factor was there as well.

To make sure the gears are getting enough oil I arranged spray heads at gears 2 through 4(930) and the R&P. 1st is just to get the car rolling.

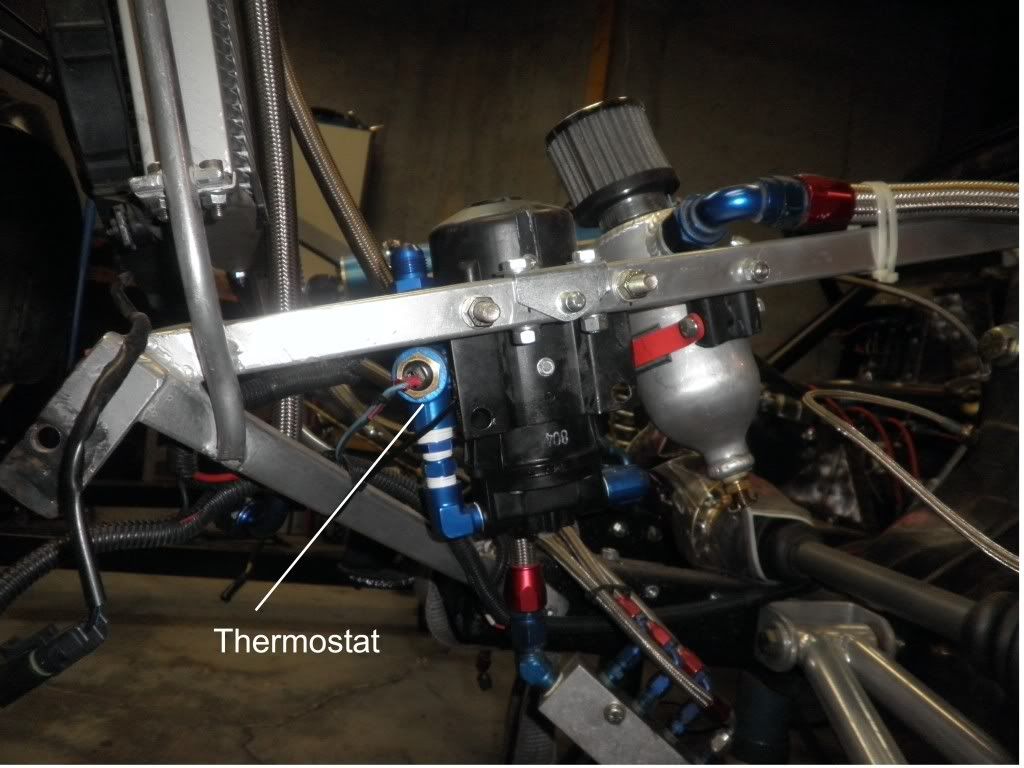

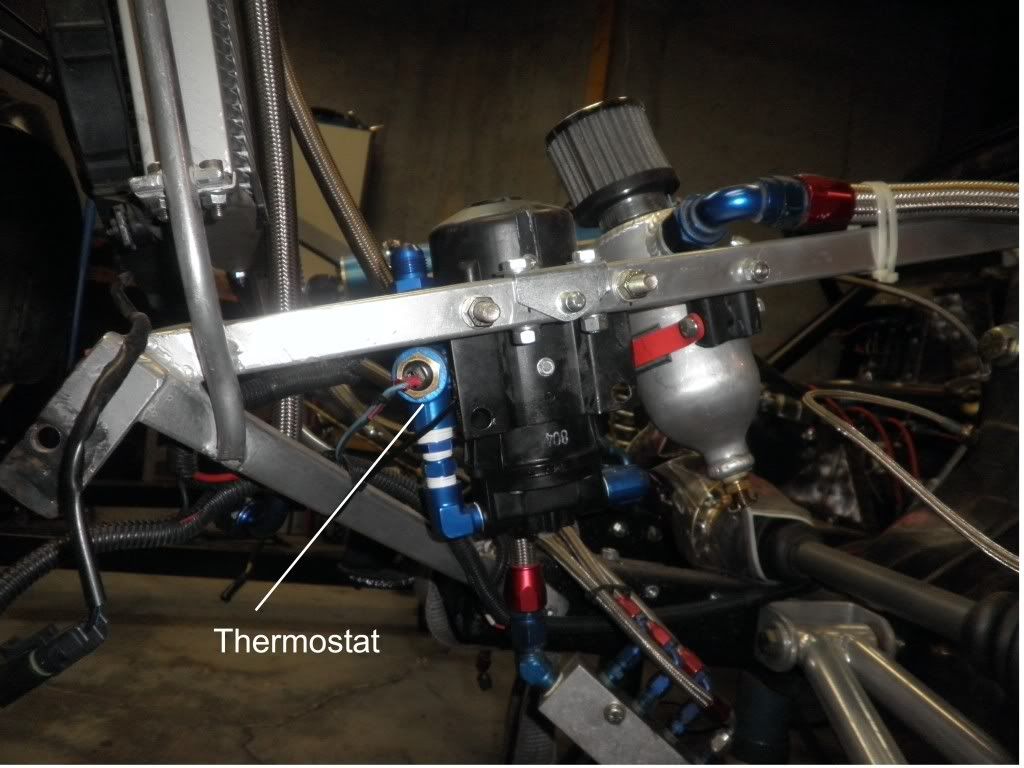

I have the pump on a switch and the fan set on a thermostat. I also wired a warning lite to the thermostat as a visual reminder that the temps were higher than normal(around 220-230), and to make sure the pump is on.

I also have a manual gauge on the dash as well.

Remember you guys with the SLC's are much lighter and won't transfer as much heat as the heavier competition cars. I think a temp guage would tell you everything you need to know, then you can spring for the cooler if you need it.

Bill

Some have internal spray bars to help out with the lubrication if the splash isn't sufficient. Remember some of us have inverted trans, so the splash is a little different. I have a cooler for my 40, but I approached the cooler option in that I already had an oil cooler on the left side and I had an open bay on the other side of the rear clip with nothing in it. So I evened things out with another matching cooler. The bling factor was there as well.

To make sure the gears are getting enough oil I arranged spray heads at gears 2 through 4(930) and the R&P. 1st is just to get the car rolling.

I have the pump on a switch and the fan set on a thermostat. I also wired a warning lite to the thermostat as a visual reminder that the temps were higher than normal(around 220-230), and to make sure the pump is on.

I also have a manual gauge on the dash as well.

Remember you guys with the SLC's are much lighter and won't transfer as much heat as the heavier competition cars. I think a temp guage would tell you everything you need to know, then you can spring for the cooler if you need it.

Bill

Yea, sounds like he'll be going in ... somewhere. It was nice holding out hope for 2 or 3minutes that maybe I wouldn't have to find room to squiggle him in, heh. I already have the cooler, just don't know where he'll be located.

Does it take more or less than 20minutes to burn 8gal of gas ..... that's my max run-time, hehe. I'll be like that Caparo T1. RAWWWWWWWWWWWWWRRRRR.....stop; fill up......RAWWWWWWWWWWWWWWWWWWR.....stop; fill up...........RAWWWWWWWWWWR; all the fun, with less risk of explosions, fire, being burnt alive, and death :shy:

I guess we will see. Eitherway that baby is going to get HOT if he runs it hard for much beyond 20 min.

Does it take more or less than 20minutes to burn 8gal of gas ..... that's my max run-time, hehe. I'll be like that Caparo T1. RAWWWWWWWWWWWWWRRRRR.....stop; fill up......RAWWWWWWWWWWWWWWWWWWR.....stop; fill up...........RAWWWWWWWWWWR; all the fun, with less risk of explosions, fire, being burnt alive, and death :shy:

Howard Jones

Supporter

My GT40 gets 8-10 MPG on track. I can run two sessions of about 20 mins each on 7 gals. My car has a 302 @ aprox 360HP. At 3 times the power you should expect to run the car for about 20 mins. Just fill it after each session. Race gas is about 8ish bucks a gallon so you are looking at about 70 dollars a session........ X 4 or 5. Friggin hell, thats just about what it cost to enter the event for the day.

And that is going to be the cheap part..........wait until you see how long the tires last............It is going to cost a $1000 a day to run that car on track, if you don't break anything. Have fun!!!

And that is going to be the cheap part..........wait until you see how long the tires last............It is going to cost a $1000 a day to run that car on track, if you don't break anything. Have fun!!!

Howard Jones

Supporter

Rear (mid sort of) gearbox stays. I went a different direction than most. I know it looks like it will swing around on he rod ends but it doesn't. They are all different lengths and at different angles. It's a way to triangulate the loads so that for the gearbox to go in any direction, up, down, or lateral it would need to stretch or compress one of the links.

I also remade the piece of the shifter mechanism so it would incorporate the lower LH rod-end mount point.

All of the material is 4140 CM. The tubing is .1 wall 5/8 OD and tapped for 3/8 24 rod-ends. The little tabs came from Speedway Racing.

I also remade the piece of the shifter mechanism so it would incorporate the lower LH rod-end mount point.

All of the material is 4140 CM. The tubing is .1 wall 5/8 OD and tapped for 3/8 24 rod-ends. The little tabs came from Speedway Racing.

Attachments

-

HPIM1007.jpg134.1 KB · Views: 455

HPIM1007.jpg134.1 KB · Views: 455 -

HPIM1011.jpg148.7 KB · Views: 417

HPIM1011.jpg148.7 KB · Views: 417 -

HPIM1009.jpg136 KB · Views: 391

HPIM1009.jpg136 KB · Views: 391 -

HPIM1008.jpg145.5 KB · Views: 414

HPIM1008.jpg145.5 KB · Views: 414 -

HPIM1013.jpg186.8 KB · Views: 399

HPIM1013.jpg186.8 KB · Views: 399 -

HPIM1014.jpg208.7 KB · Views: 398

HPIM1014.jpg208.7 KB · Views: 398 -

HPIM1015.jpg223.4 KB · Views: 426

HPIM1015.jpg223.4 KB · Views: 426 -

HPIM1016.jpg167.1 KB · Views: 399

HPIM1016.jpg167.1 KB · Views: 399 -

HPIM1017.jpg179.8 KB · Views: 425

HPIM1017.jpg179.8 KB · Views: 425 -

HPIM1019.jpg197.1 KB · Views: 440

HPIM1019.jpg197.1 KB · Views: 440 -

HPIM1018.jpg180.5 KB · Views: 366

HPIM1018.jpg180.5 KB · Views: 366

Last edited:

Howard Jones

Supporter

Expansion tank done. It fits right where it needs to go. Really its the only place it will fit. At least I don't need to cut a hole in the bodywork or feed some kind of spout into where the the fill cap would be to fill the system. The fill neck sticks out and clears the bodywork nicely.

The small ports on the side are for the bleed system and the big one on the botom goes to the coolent system pipe that returns to the pump.

It holds a little more than 1.5 quarts.

Pics below. By the way what pressure cap should I use?

The small ports on the side are for the bleed system and the big one on the botom goes to the coolent system pipe that returns to the pump.

It holds a little more than 1.5 quarts.

Pics below. By the way what pressure cap should I use?

Attachments

Last edited:

Howard Jones

Supporter

Doc, in the third pic from the left I have it held up in place. More or less behind the fuel filler and as high as possible. This is the main reason I moved the inlet for the fuel tank.

55, Thanks, 14PSI it is. I was going for a mount that worked and didn't interfere with the diffuser at the rear. There is limmited space behind the GB, especially side to side, and I am trying to save as much as I can for wing and rear bodywork hinge mounts. Thanks for the comliment on my welding. This is the first time I met my own standards. Making things that can be welded up on the bench is much easier. The real welding in done overhead and in tight spots. I'm not sure I will be able to always do all of my own welding, but at least I have the proper equipment and I can always ask some GOOD welder to do it for me without moving the car away from home.

Ultimately building a car like this is a exercise in packaging. Basically don't waste space and at the same time build it so it can be worked on easily. This requires many hours of thinking and looking at other people's idea's. I always look hard at other race cars when I get a chance and have begun keeping pictures of things like brackets and such on other cars in a "good idea" file.

55, Thanks, 14PSI it is. I was going for a mount that worked and didn't interfere with the diffuser at the rear. There is limmited space behind the GB, especially side to side, and I am trying to save as much as I can for wing and rear bodywork hinge mounts. Thanks for the comliment on my welding. This is the first time I met my own standards. Making things that can be welded up on the bench is much easier. The real welding in done overhead and in tight spots. I'm not sure I will be able to always do all of my own welding, but at least I have the proper equipment and I can always ask some GOOD welder to do it for me without moving the car away from home.

Ultimately building a car like this is a exercise in packaging. Basically don't waste space and at the same time build it so it can be worked on easily. This requires many hours of thinking and looking at other people's idea's. I always look hard at other race cars when I get a chance and have begun keeping pictures of things like brackets and such on other cars in a "good idea" file.

Your my hero Howard. Nice work on the tank as always and your welding is def improving! I'll have to get you over HERE for some guest welding. Could not agree more on the spending much time thinking the packaging, access, best location aspect of EVERY LITTLE THING. I spent way too much time figuring out two access panels in the front of the foot box on my car (I have a real problem stuffing myself in a foot box head first). This is possible because of the "empty" front area on my car and makes getting wrenches on the pedal assy lines and suspension pivots/brackets way easier.

Howard Jones

Supporter

Here's where it goes. I need a couple of more fittings from Summit and this part is done.

Oh, I did the math and it's 1.74 quarts. That ought to give me a quart in the tank and a little less than 2 inchs of air at the top.

Oh, I did the math and it's 1.74 quarts. That ought to give me a quart in the tank and a little less than 2 inchs of air at the top.

Attachments

Last edited:

Similar threads

- Replies

- 12

- Views

- 875