You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Roof line?

- Thread starter jlwdvm

- Start date

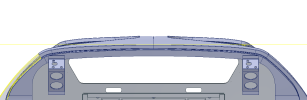

The roof is a compound surface, so yes; curved. Or are you wondering about that small profile that most of the fiberglass replicas got?Did original MK1's have a subtle arc to the roof where the spider meets the rear clam...or was this area flat?

Joe, the rear edge of the roof is curved in two directions. The rear firewall It is not a straight line across the car, with the center top of the rear edge of the roof extending backwards a little bit relative to the corner near the door which is slightly forward.

When viewed from behind the car the center line of the roof is again slightly higher at the mating surface than the corners at the door. I have been trying to draw this up in CAD the last couple of nights and only managed to get my head around this detail last night. I am yet to get a solution implemented in CAD though. Just noticed the same details last night when I could not make my part match up with the reference geometry. May also explain why drawings of this part are hard to come by as I suspect a lot of this area of the car was a coach-built parts from an artisan craftsman.

Something that would have been easy enough to do with a shrinker / stretcher on the turned edges, but rather hard to draw on a drafting table.

When viewed from behind the car the center line of the roof is again slightly higher at the mating surface than the corners at the door. I have been trying to draw this up in CAD the last couple of nights and only managed to get my head around this detail last night. I am yet to get a solution implemented in CAD though. Just noticed the same details last night when I could not make my part match up with the reference geometry. May also explain why drawings of this part are hard to come by as I suspect a lot of this area of the car was a coach-built parts from an artisan craftsman.

Something that would have been easy enough to do with a shrinker / stretcher on the turned edges, but rather hard to draw on a drafting table.

That's what I needed...Thanks you! Would you happen to have a side view of the car that shows ride height of the front clam as compared to the rockers? My clam hinges haven't been finalized yet and I need to know ground clearance of the front clam at the front of the wheel well...if this makes sense.

Seems to be about 230-240mm

Joe,

Don't glue that plywood board in until you have sorted out all your body gaps. As soon as you glue that in, you end up locking down the shape of the rear clip and it can get very hard to adjust it from side to side.

Whilst that is still free, you can generally move each side independently and adjust one side without distorting the other.

Will you make a fiberglass version of the panel for the final part?

I guess you can screw through the skin into the wood to temporarily attach it for shape.

Ryan

Don't glue that plywood board in until you have sorted out all your body gaps. As soon as you glue that in, you end up locking down the shape of the rear clip and it can get very hard to adjust it from side to side.

Whilst that is still free, you can generally move each side independently and adjust one side without distorting the other.

Will you make a fiberglass version of the panel for the final part?

I guess you can screw through the skin into the wood to temporarily attach it for shape.

Ryan

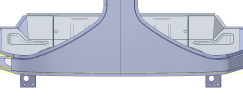

Right now, even without the inner structure, I can open and close the rear clam (with it hitting the locating pins) by myself. The bottom of the clam is set and latches are in place. A preliminary fit of body panels was done prior to finalizing the pin locations. My idea is that when the inner structure and wheel wells are attached to the clam, it will prevent the lower front corners of the clam from flexing and bowing out when the clam is moved up and down during opening/closing.

I’ve gone back and forth on what to make the panels out of. I think I’m going to use the 1/4” plywood and fiberglass 1708 over it.

I’ve gone back and forth on what to make the panels out of. I think I’m going to use the 1/4” plywood and fiberglass 1708 over it.

Why not save the weight and make them from 1/8” plywood & fiberglass or even aluminum? My thoughts are aluminum as I’m going to Rhinoline the wheel wells anyway but am open to other ways & materials as well.Right now, even without the inner structure, I can open and close the rear clam (with it hitting the locating pins) by myself. The bottom of the clam is set and latches are in place. A preliminary fit of body panels was done prior to finalizing the pin locations. My idea is that when the inner structure and wheel wells are attached to the clam, it will prevent the lower front corners of the clam from flexing and bowing out when the clam is moved up and down during opening/closing.

I’ve gone back and forth on what to make the panels out of. I think I’m going to use the 1/4” plywood and fiberglass 1708 over it.View attachment 146283

Sorry for the thread migration.

1/8" sanded plywood had crossed my mind, but I'm not worried about saving a pound here and there, I'm more concerned with the panels being flat and rigid. Also, what little inner structure-wheel well that is bonded to the clam at AP is 1/4" as well...so the seam will match up well with the plywood extension of the wheel well. I'll be using Raptor liner on the wheel wells, and probably the rest of the underside of the clam as well.

Similar threads

- Replies

- 1

- Views

- 565

- Replies

- 0

- Views

- 335