Ah, OK, thanks for the explanation. 2" should be OK to still allow for the filler cap and pipe bend. k

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Old Tornado- Bringing Back to Life

- Thread starter Chally72

- Start date

Here it is all freshly welded. This will allow the inner framerail to now be the limit for the wheel, rather than the paneling for the outer corner. Still waiting on the darned arbor for the hole saw, or the new suspension would be bolted on one side.

Attachments

I promised myself I wouldn't update this until I was 100% finished with the suspension front and rear, but I can't help it...

Here are some pictures of the aluminum rear uprights I designed and milled. We got a new milling machine at work and of course I needed a 'training' part to learn how to program the thing. These bolt to stock C5 Corvette hubs, rotors, calipers, mounting brackets, and ebrake assembly. I'm not quite done with the a-arm mounting arms that come off it. (PS...ignore the rusty rotor. For mockup purposes only, I swear!)

These bolt to stock C5 Corvette hubs, rotors, calipers, mounting brackets, and ebrake assembly. I'm not quite done with the a-arm mounting arms that come off it. (PS...ignore the rusty rotor. For mockup purposes only, I swear!)

I've taken a break from some of the contract work I've been doing at night, and set myself a 50hr workweek limit. Hopefully it will help in spending time with friends, family, and GT40. I've been flat-out for over a year and it finally got to be too much.

More pictures soon

Here are some pictures of the aluminum rear uprights I designed and milled. We got a new milling machine at work and of course I needed a 'training' part to learn how to program the thing.

I've taken a break from some of the contract work I've been doing at night, and set myself a 50hr workweek limit. Hopefully it will help in spending time with friends, family, and GT40. I've been flat-out for over a year and it finally got to be too much.

More pictures soon

Attachments

Hi Dylan,

Wow! That is really first class. You are really doing a fantastic job.

Bob Woods

Wow! That is really first class. You are really doing a fantastic job.

Bob Woods

A long update to bring this build log up to the present!

I cut apart the frontend and welded in new upright columns and cross supports. The tubing that supports the coilover mount is now actually braced across the frame. The front columns might get a smaller cross brace. I need to finalize brake component/battery/etc...location up front before I decide how to tie that together. The radiator will be held on by an aluminum structure that bolts onto the frame. The front frame is just sprayed down with rustoleum for now. I'm sure I'll be back in it welding all sorts of cap tubes for other mounting points.

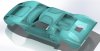

I am in the middle of figuring out exactly where to mount the coilovers on the lower A-arms. This required me to drag out the body and start measuring, so I got to see it sitting on the car again for the first time since 2012. The upper a-arm design and upper ball joint will be changing, and now that I have access to a mill I will most likely be remaking all the arms out of aluminum, but I want to finish the arms I started with, for the geometry prove-out and because I'm so close to done with them. The car's track width is widened about 2" in the front and the rear compared to original Tornado numbers. Camber gain is at around 0.75°/in, with caster at 7.2° at ride height.

The upper a-arm design and upper ball joint will be changing, and now that I have access to a mill I will most likely be remaking all the arms out of aluminum, but I want to finish the arms I started with, for the geometry prove-out and because I'm so close to done with them. The car's track width is widened about 2" in the front and the rear compared to original Tornado numbers. Camber gain is at around 0.75°/in, with caster at 7.2° at ride height.

I made some aluminum brake duct backing plates for the Wilwood spindles. I had to make a redneck forming tool out of some metal disks and rings, but it came out really well. The form stiffens the heck out of the 0.090" aluminum, so I can push the gap extremely close to the rotor and not worry about the backing plate flexing and touching the rotor. I've had some experience making ducts for 2005-2012 Mustangs after I got angry at the price Ford Racing wanted for a set and the amount that mine squealed under cornering when touching the rotor, so those lessons came in handy here.

I milled a few more odds and ends like door handles for myself, too. I bought some from Tornado last year, but it was a good part to 'learn the mill' with.

I've been ignoring the rear suspension but will be starting on the rear upright bolt on arm mounts now that both uprights are done and ready to bolt together. I'm split between powdercoating or anodizing them. I spent so much time on them that I'm sad they won't be more visible when the car is together.

I ordered wheels from HRE and got Michelin Pilot Super Sports. No, these aren't very classic looking wheels...but my choice of brakes didn't allow me that option. . The fronts are 285/35/18 and rears are 345/30/19. The rear clip will need mild flares glassed in, but it will be much more subtle than actual Gulf flares.

. The fronts are 285/35/18 and rears are 345/30/19. The rear clip will need mild flares glassed in, but it will be much more subtle than actual Gulf flares.

I got my Coyote crate engine delivered as well. A nice 25th birthday present. I have the intake all flipped around, but I still have to modify the harness. Thanks to Renato for giving me a detailed rundown on what to expect. It was easier than anticipated and only took about two hours even with me being excessively careful about plastic grit. Unfortunately, the engine will have to stay at my work for a while...I am not ready yet with the engine/trans mounts, and the garage is unheated so I don't want to leave the engine sitting in it any longer than absolutely necessary for fitup.

I cut apart the frontend and welded in new upright columns and cross supports. The tubing that supports the coilover mount is now actually braced across the frame. The front columns might get a smaller cross brace. I need to finalize brake component/battery/etc...location up front before I decide how to tie that together. The radiator will be held on by an aluminum structure that bolts onto the frame. The front frame is just sprayed down with rustoleum for now. I'm sure I'll be back in it welding all sorts of cap tubes for other mounting points.

I am in the middle of figuring out exactly where to mount the coilovers on the lower A-arms. This required me to drag out the body and start measuring, so I got to see it sitting on the car again for the first time since 2012.

I made some aluminum brake duct backing plates for the Wilwood spindles. I had to make a redneck forming tool out of some metal disks and rings, but it came out really well. The form stiffens the heck out of the 0.090" aluminum, so I can push the gap extremely close to the rotor and not worry about the backing plate flexing and touching the rotor. I've had some experience making ducts for 2005-2012 Mustangs after I got angry at the price Ford Racing wanted for a set and the amount that mine squealed under cornering when touching the rotor, so those lessons came in handy here.

I milled a few more odds and ends like door handles for myself, too. I bought some from Tornado last year, but it was a good part to 'learn the mill' with.

I've been ignoring the rear suspension but will be starting on the rear upright bolt on arm mounts now that both uprights are done and ready to bolt together. I'm split between powdercoating or anodizing them. I spent so much time on them that I'm sad they won't be more visible when the car is together.

I ordered wheels from HRE and got Michelin Pilot Super Sports. No, these aren't very classic looking wheels...but my choice of brakes didn't allow me that option.

I got my Coyote crate engine delivered as well. A nice 25th birthday present. I have the intake all flipped around, but I still have to modify the harness. Thanks to Renato for giving me a detailed rundown on what to expect. It was easier than anticipated and only took about two hours even with me being excessively careful about plastic grit. Unfortunately, the engine will have to stay at my work for a while...I am not ready yet with the engine/trans mounts, and the garage is unheated so I don't want to leave the engine sitting in it any longer than absolutely necessary for fitup.

Attachments

-

20140227_114656.jpg118.8 KB · Views: 358

20140227_114656.jpg118.8 KB · Views: 358 -

20140227_115740.jpg133 KB · Views: 361

20140227_115740.jpg133 KB · Views: 361 -

20140321_140043.jpg226.6 KB · Views: 385

20140321_140043.jpg226.6 KB · Views: 385 -

20140308_150246.jpg80.8 KB · Views: 379

20140308_150246.jpg80.8 KB · Views: 379 -

20140308_171930.jpg237.4 KB · Views: 366

20140308_171930.jpg237.4 KB · Views: 366 -

20140415_190841.jpg221 KB · Views: 387

20140415_190841.jpg221 KB · Views: 387 -

20140420_191312.jpg199.2 KB · Views: 376

20140420_191312.jpg199.2 KB · Views: 376 -

20140403_163834.jpg212.7 KB · Views: 387

20140403_163834.jpg212.7 KB · Views: 387 -

20140430_141055.jpg64 KB · Views: 317

20140430_141055.jpg64 KB · Views: 317 -

20140430_143425.jpg151.4 KB · Views: 321

20140430_143425.jpg151.4 KB · Views: 321 -

20140430_143445.jpg140.3 KB · Views: 371

20140430_143445.jpg140.3 KB · Views: 371 -

20140430_143546.jpg170.3 KB · Views: 331

20140430_143546.jpg170.3 KB · Views: 331 -

20140506_185248.jpg171.7 KB · Views: 371

20140506_185248.jpg171.7 KB · Views: 371 -

20140506_185339.jpg187.5 KB · Views: 423

20140506_185339.jpg187.5 KB · Views: 423 -

20140506_185705.jpg188.1 KB · Views: 365

20140506_185705.jpg188.1 KB · Views: 365 -

20140515_141333.jpg123.6 KB · Views: 332

20140515_141333.jpg123.6 KB · Views: 332 -

20140515_141346.jpg117.6 KB · Views: 313

20140515_141346.jpg117.6 KB · Views: 313 -

20140517_122402.jpg169.9 KB · Views: 348

20140517_122402.jpg169.9 KB · Views: 348 -

20140517_122417.jpg148.4 KB · Views: 353

20140517_122417.jpg148.4 KB · Views: 353 -

20140520_185933.jpg165.7 KB · Views: 335

20140520_185933.jpg165.7 KB · Views: 335 -

20140520_185956.jpg62.6 KB · Views: 348

20140520_185956.jpg62.6 KB · Views: 348 -

20140520_190017.jpg126.6 KB · Views: 303

20140520_190017.jpg126.6 KB · Views: 303 -

20140520_190107.jpg160.6 KB · Views: 384

20140520_190107.jpg160.6 KB · Views: 384 -

20140520_190129.jpg168.8 KB · Views: 299

20140520_190129.jpg168.8 KB · Views: 299

Dylan,

Thanks for the update. Wow, you are inspiring me...

-Bob Woods

Thanks for the update. Wow, you are inspiring me...

-Bob Woods

Yeah, very nice update. I don't suppose you'd be interested in making any more door handles?

Dylan,

Long time lurker and it looks like Im going to be taking over a RF GT40 build here pretty soon.

Firstly, really incredible work on your project... nice job.

Re your frame, are you doing any FEA on it to see what mods help with torsional stiffness? What program did you model it in?

David

Long time lurker and it looks like Im going to be taking over a RF GT40 build here pretty soon.

Firstly, really incredible work on your project... nice job.

Re your frame, are you doing any FEA on it to see what mods help with torsional stiffness? What program did you model it in?

David

Bob, you're a little ahead of me already....

Simon, I don't think I could beat out the prices of someone like Tornado that just has the door handles cast. Plus I still have to make the actual housing bit.

David, firstly thanks for your compliments and hope to see your build soon! I don't have any FEA abilities myself, but I stripped and simplified my 'original' and 'modified' frame models enough that I could have a friend do some FEA comparisons for me. Relative to the original, the front section is around 25-30% stiffer torsionally. Not to mention the benefits of less flex at the coilover mount points. Everything you see is modeled in Solid Edge.

Simon, I don't think I could beat out the prices of someone like Tornado that just has the door handles cast. Plus I still have to make the actual housing bit.

David, firstly thanks for your compliments and hope to see your build soon! I don't have any FEA abilities myself, but I stripped and simplified my 'original' and 'modified' frame models enough that I could have a friend do some FEA comparisons for me. Relative to the original, the front section is around 25-30% stiffer torsionally. Not to mention the benefits of less flex at the coilover mount points. Everything you see is modeled in Solid Edge.

I see you went with a Coyote. Guessing it's not the Aluminator variant by the look but the size is identical to mine and will be the same as Renato's.

Have you tried to fit everything? I think given that you have a Tornado not designed for the Coyote you might run into the same issue Renato did in that the thing is a bit too long depending on your transaxle and adapter. I'm going to go with a 15mm thick steel one to give me the room I need and still may have to notch something here and there. Renato did more surgery to get his to fit but his adapter was 1.75" thick aluminum I believe.

Have you tried to fit everything? I think given that you have a Tornado not designed for the Coyote you might run into the same issue Renato did in that the thing is a bit too long depending on your transaxle and adapter. I'm going to go with a 15mm thick steel one to give me the room I need and still may have to notch something here and there. Renato did more surgery to get his to fit but his adapter was 1.75" thick aluminum I believe.

Hi Darrin,

Yes, it is an aluminator crate!

I have done extensive modifications to the frame to fit the Coyote. The changes to the Tornado frame for the Coyote engine are highlighted in one of my earlier posts, but basically require cutting out and welding in new upper engine bay rails back to the horseshoe, and also cutting out the interior bulkhead tubing inside the bulkhead hoop and redoing the angle.

My adapter is Eric's (Kitcarchassis) thick aluminum one, and I'm using an Audi 01E transaxle. The bulkhead will be tilted even farther forward than the Tornado Coyote chassis to give me some more room to play with, and I'm raising the tail of the drivetrain to get the axles in a better position.

Yes, it is an aluminator crate!

I have done extensive modifications to the frame to fit the Coyote. The changes to the Tornado frame for the Coyote engine are highlighted in one of my earlier posts, but basically require cutting out and welding in new upper engine bay rails back to the horseshoe, and also cutting out the interior bulkhead tubing inside the bulkhead hoop and redoing the angle.

My adapter is Eric's (Kitcarchassis) thick aluminum one, and I'm using an Audi 01E transaxle. The bulkhead will be tilted even farther forward than the Tornado Coyote chassis to give me some more room to play with, and I'm raising the tail of the drivetrain to get the axles in a better position.