Terry Oxandale

Skinny Man

Thanks for the tip Russell. I'll check it out. One of the things I noticed on Udo's pieces was that he double-clipped the CV on each end of the shaft. When I had my 240Z (I fabricated some adapter plates and used 930 joints), I also did the same thing, and it worked great, but on this project I chose instead to try having no clips, and let the axle float on the splines in the CVs (bumps the stubs on each side I suppose, but thus far, no wear marks on either end). The sand racing guys use this method regularly from what I understand due to their 8" to 18"+ travel designs. After some research, and consistent responses to my concerns, I chose to mimic that set-up. The only warning I got was that the splines may overheat depending on how much travel, torque, and track conditions I had in competition (how much sliding took place on the splines under torque). I shared my suspension design with them, and my use for the car, and these seeming experts said I didn't have a thing to worry about.

So...my splines are 3" long on each end (typical aftermarket axle that comes in 1/4" increments), so that allows for a lot more travel then I would ever see (plunge is enough just by itself). So far, with over a 1000 street miles, and several track days, no issues. Oh, and they are really easy to remove! Just slide it off

At static ride height, I can move the axle laterally about 3/8" from stop to stop, so it should never bind, and allows me more flexibility than I'd ever need in moving the upright inboard, or especially outboard if needed for later changes to suspension/wheel parameters (longer control arms).

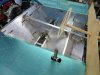

Photo from very early on in the build showing exposed splines, which are easily protected by the normal boot length.

So...my splines are 3" long on each end (typical aftermarket axle that comes in 1/4" increments), so that allows for a lot more travel then I would ever see (plunge is enough just by itself). So far, with over a 1000 street miles, and several track days, no issues. Oh, and they are really easy to remove! Just slide it off

At static ride height, I can move the axle laterally about 3/8" from stop to stop, so it should never bind, and allows me more flexibility than I'd ever need in moving the upright inboard, or especially outboard if needed for later changes to suspension/wheel parameters (longer control arms).

Photo from very early on in the build showing exposed splines, which are easily protected by the normal boot length.

Last edited: