Thanks Kalun, I will see about the rack when Fran gets some info on the situation.

FITTING BODY PANELS

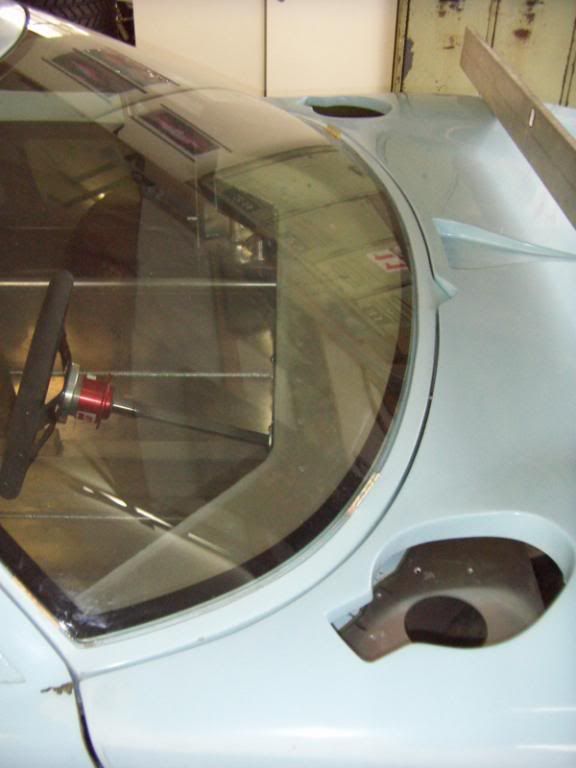

I have kept moving on the build. After loosely fitting the LH & RH rocker panels I fitted the front clip. I have to do some bobbin adjustments to get this right as it sits quite high in front of the window (thanks RCR Australia for the emails on this).

I then decided to put the doors on. I made 4 aluminium backing plates with nutserts in them to make fitting the hinges to the chassis much easier (no spanner behind to hold the nuts). I made 4 horizontal slotted holes in the chassis, with the vertical slots in the hinge this will allow hinge movement to align the doors.

As we all know the standard design uses two bolts to attach each of the hinges (a bolt and nut on the top and another set at the bottom). I found it a little tricky to fit the door on my own like that. So by following some other builds as inspiration I purchased two 1/2" UNF x 10" long grade 8 bolts to replace the standard items. This allows me to run one long bolt down the door hinge. I also purchased different thickness nylon washers to place between the moving hinge elements to get a tight, rattle free fit.

The door fitted well but still needs a lot of adjustment to the other panels. I'm reluctant to trim any panels at this time as I have heard people say that they got good preliminary fits without shaving parts. We will see if I am good enough to get that to happen! Reading other build threads on this forum has given me a serious inferiority complex :laugh:

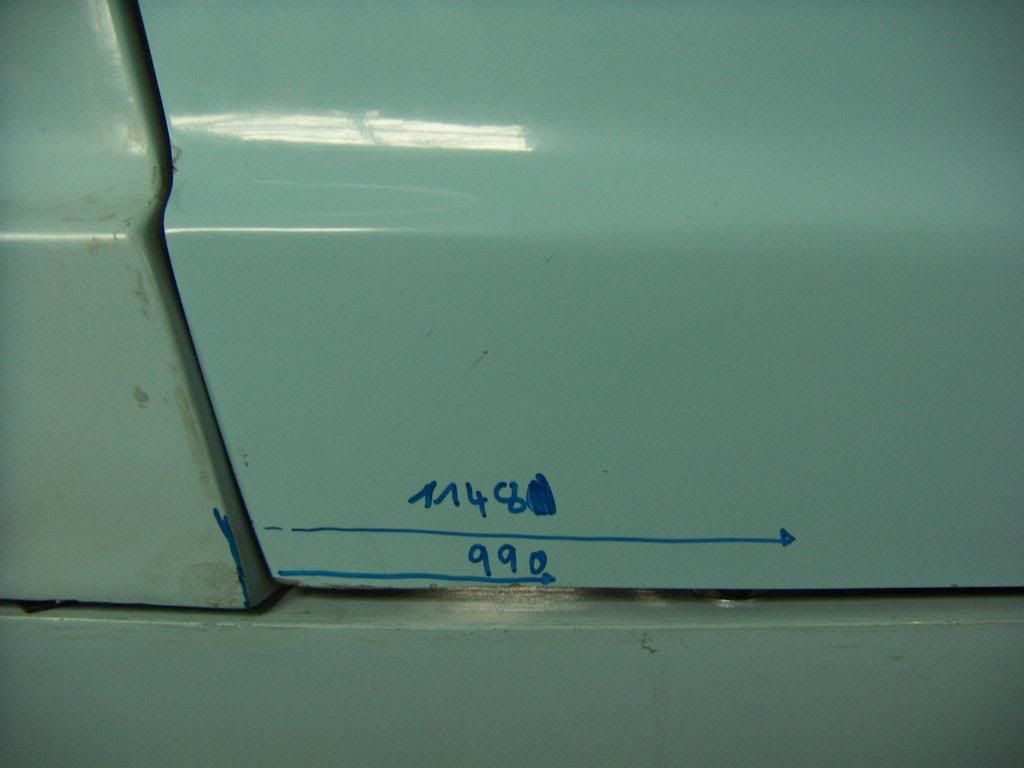

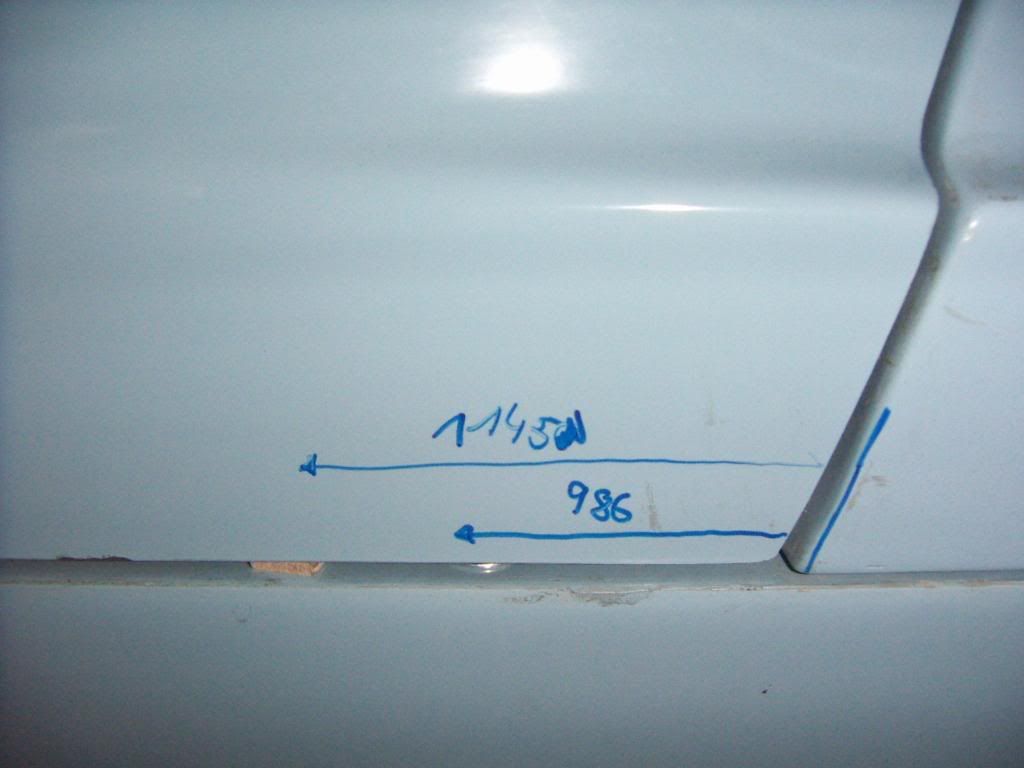

Also not sure about the 66" dimension from rocker to rocker. It looks a little wide for my front clip (I have to stretch the front clip to get the alignment pins to lock in, this may be normal?) and I would need to space my hinges off the chassis by quite a lot (~15mm) to get the front of the door to line up to the rocker panel. Just an observation and I'm not worried as I really need to get everything on before moving parts around for fit.

I may weld the lower nut to the chassis hinge as it will make the fitment and removal of the bolt even easier. I may also weld a tube between the door hinge plates to help alignment of the bolt through the hinge points.

Not sure if that will limit the adjustability of the door though, any comments would be appreciated.

FITTING BODY PANELS

I have kept moving on the build. After loosely fitting the LH & RH rocker panels I fitted the front clip. I have to do some bobbin adjustments to get this right as it sits quite high in front of the window (thanks RCR Australia for the emails on this).

I then decided to put the doors on. I made 4 aluminium backing plates with nutserts in them to make fitting the hinges to the chassis much easier (no spanner behind to hold the nuts). I made 4 horizontal slotted holes in the chassis, with the vertical slots in the hinge this will allow hinge movement to align the doors.

As we all know the standard design uses two bolts to attach each of the hinges (a bolt and nut on the top and another set at the bottom). I found it a little tricky to fit the door on my own like that. So by following some other builds as inspiration I purchased two 1/2" UNF x 10" long grade 8 bolts to replace the standard items. This allows me to run one long bolt down the door hinge. I also purchased different thickness nylon washers to place between the moving hinge elements to get a tight, rattle free fit.

The door fitted well but still needs a lot of adjustment to the other panels. I'm reluctant to trim any panels at this time as I have heard people say that they got good preliminary fits without shaving parts. We will see if I am good enough to get that to happen! Reading other build threads on this forum has given me a serious inferiority complex :laugh:

Also not sure about the 66" dimension from rocker to rocker. It looks a little wide for my front clip (I have to stretch the front clip to get the alignment pins to lock in, this may be normal?) and I would need to space my hinges off the chassis by quite a lot (~15mm) to get the front of the door to line up to the rocker panel. Just an observation and I'm not worried as I really need to get everything on before moving parts around for fit.

I may weld the lower nut to the chassis hinge as it will make the fitment and removal of the bolt even easier. I may also weld a tube between the door hinge plates to help alignment of the bolt through the hinge points.

Not sure if that will limit the adjustability of the door though, any comments would be appreciated.