So I traced my leaking refrigerant issue to the compressor after pressurizing the system and hearing a loud hissing in that area. It was not coming from either of the lines going in and out of the compressor but from the front area so assuming a bad front seal.

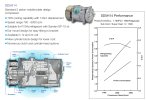

As the compressor was new I wonder if this could be caused by the fact that it is mounted upside down? It’s a Sanden SD7B10 (Vintage Air). I think that’s the kind they called the “peanut” compressor and the only way I could get it to fit was by hanging it with the lines facing the bottom. It still turns in the correct direction, but I wonder if this could cause an lubrication issue? Anyone successfully running their compressors in this orientation?

As the compressor was new I wonder if this could be caused by the fact that it is mounted upside down? It’s a Sanden SD7B10 (Vintage Air). I think that’s the kind they called the “peanut” compressor and the only way I could get it to fit was by hanging it with the lines facing the bottom. It still turns in the correct direction, but I wonder if this could cause an lubrication issue? Anyone successfully running their compressors in this orientation?