Fuel Filler Solved

OK, I have my solution. Thanks to everyone for the help and thoughts. So, after buying and trying and cutting and grinding straight pipe, 45 degree mandrel bend pipes, 60 degree mandrel bent pipes, inflexible “flexible fuel hose”, other fuel hose and trying many thing to cut and index the parts together and many hours, I finally have something that I am satisfied with and will work…… I think.

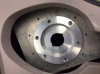

First picture is the top picture, no value in that except to show that the top plate is held in place quite easily without much force, as evidenced by having just one screw to hold it nearly in place.

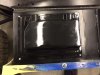

Second picture is the solution installed, or almost installed. Everything is there, except a couple of hose clamps and one more section of fuel line that connects the bottom pipe to the top of the tank. I didn’t want to put that on one more time since I learned from experience just how difficult it is to remove the hose from the top of the tank given the gripping ridges that are present on the neck of the tank.

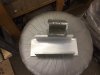

The third picture shows everything the comprises the solution. Here is the explanation of how each of the parts was “tuned” or not.

Starting from the left. The fuel top as received from RCR, it was slightly modified to cut the bottom neck to 1 inch long. This provides just a little bit more clearance to make the curve ahead of the frame, and still provides plenty of room to affix the hose and the clamp. The top “ring” shown was fabricated by me, it is ¼ inch thick aluminum plate that matches the holes and goes underneath the fuel top, it fits within the Lemans cap just fine, and helps provide just a little bit more clearance. Of course the four clamps to hold the hoses. The “magic” part that finally got me to the goal line is the longer black hose. It is a “2" Ultra Flexible Oil, Gas & Diesel Fuel Filler Hose Section (10" TO 7" Long)” from Filler Neck Supply company. I did cut 1.5 inches from the top of the hose (their description and instructions say you can cut 1.5 inches from either or both ends thus making it the variable length). This then attaches to the top part, and makes the bend before the frame with very little effort. This actually is flexible and is a very cool part. The ridges you see are metal wire in the center part, which actually lets it make a 90 degree bend without collapsing, thus making the turn I need. Added benefit is that even though there is slight contact with the frame (as was the case with the metal parts, or very close), this won’t rattle. Then the shiny part is most of a 60 degree mandrel bent stainless steel pipe. Cut just above the curve, leaving enough of a flat lip just where it contact the neck of the tank to affix a hose between it and the tank and clamp it. The longer flat portion goes about 3 inches into the longer end of the flexible hose.

Note the two shorter pieces of fuel hose. I will probably end up buying some more fuel hose, so that I can have a 4 inch long piece or so, 2.5 inches would completely cover the neck of the tank and then go 1.5 inches onto the bent part of the pipe and be clamped at each end. The piece showing at the bottom of the pipe bend is the 1.5 inches left from the end of the flex hose. The other piece shown is not used, it is a 2 inch long piece of the previous inflexible “flexible” fuel hose that I bought. It is very heavy, and almost impossible to put much of a bend in it. 3 feet for sixty bucks. I have a couple of big pieces left if anyone wants it. I could use that, but it is heavy and very hard to cut. If nothing else, I could cut a 4 inch piece of that and use it at the bottom.

Done. Hopefully this helps someone else out.

OK, I have my solution. Thanks to everyone for the help and thoughts. So, after buying and trying and cutting and grinding straight pipe, 45 degree mandrel bend pipes, 60 degree mandrel bent pipes, inflexible “flexible fuel hose”, other fuel hose and trying many thing to cut and index the parts together and many hours, I finally have something that I am satisfied with and will work…… I think.

First picture is the top picture, no value in that except to show that the top plate is held in place quite easily without much force, as evidenced by having just one screw to hold it nearly in place.

Second picture is the solution installed, or almost installed. Everything is there, except a couple of hose clamps and one more section of fuel line that connects the bottom pipe to the top of the tank. I didn’t want to put that on one more time since I learned from experience just how difficult it is to remove the hose from the top of the tank given the gripping ridges that are present on the neck of the tank.

The third picture shows everything the comprises the solution. Here is the explanation of how each of the parts was “tuned” or not.

Starting from the left. The fuel top as received from RCR, it was slightly modified to cut the bottom neck to 1 inch long. This provides just a little bit more clearance to make the curve ahead of the frame, and still provides plenty of room to affix the hose and the clamp. The top “ring” shown was fabricated by me, it is ¼ inch thick aluminum plate that matches the holes and goes underneath the fuel top, it fits within the Lemans cap just fine, and helps provide just a little bit more clearance. Of course the four clamps to hold the hoses. The “magic” part that finally got me to the goal line is the longer black hose. It is a “2" Ultra Flexible Oil, Gas & Diesel Fuel Filler Hose Section (10" TO 7" Long)” from Filler Neck Supply company. I did cut 1.5 inches from the top of the hose (their description and instructions say you can cut 1.5 inches from either or both ends thus making it the variable length). This then attaches to the top part, and makes the bend before the frame with very little effort. This actually is flexible and is a very cool part. The ridges you see are metal wire in the center part, which actually lets it make a 90 degree bend without collapsing, thus making the turn I need. Added benefit is that even though there is slight contact with the frame (as was the case with the metal parts, or very close), this won’t rattle. Then the shiny part is most of a 60 degree mandrel bent stainless steel pipe. Cut just above the curve, leaving enough of a flat lip just where it contact the neck of the tank to affix a hose between it and the tank and clamp it. The longer flat portion goes about 3 inches into the longer end of the flexible hose.

Note the two shorter pieces of fuel hose. I will probably end up buying some more fuel hose, so that I can have a 4 inch long piece or so, 2.5 inches would completely cover the neck of the tank and then go 1.5 inches onto the bent part of the pipe and be clamped at each end. The piece showing at the bottom of the pipe bend is the 1.5 inches left from the end of the flex hose. The other piece shown is not used, it is a 2 inch long piece of the previous inflexible “flexible” fuel hose that I bought. It is very heavy, and almost impossible to put much of a bend in it. 3 feet for sixty bucks. I have a couple of big pieces left if anyone wants it. I could use that, but it is heavy and very hard to cut. If nothing else, I could cut a 4 inch piece of that and use it at the bottom.

Done. Hopefully this helps someone else out.