You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

H Craft GT-R, Jared's build.

Rufus you were at RCR Allan and myself are still in the waiting mode for our GTR’s Fran mentioned to Allan with the movie cars in the mix everything with customers cars got delayed I have had my car on order since March and Allan way before me

Neil

Supporter

Andy;

Nice work on your build. One suggestion: consider using Gates "Power Band" hose clamps instead of conventional worm-drive clamps. These are heat-shrink bands that are very strong and provide a uniform grip around the hose. Also, they do not damage the rubber of softer hoses such as silicone.

Of course you will need to have one removable clamp now and then so the hard line can be disassembled but I'd recommend using a T-bolt clamp for that.

Regards, Neil Tucson, AZ

Nice work on your build. One suggestion: consider using Gates "Power Band" hose clamps instead of conventional worm-drive clamps. These are heat-shrink bands that are very strong and provide a uniform grip around the hose. Also, they do not damage the rubber of softer hoses such as silicone.

Of course you will need to have one removable clamp now and then so the hard line can be disassembled but I'd recommend using a T-bolt clamp for that.

Regards, Neil Tucson, AZ

Attachments

Ron McCall

Supporter

Andy;

Nice work on your build. One suggestion: consider using Gates "Power Band" hose clamps instead of conventional worm-drive clamps. These are heat-shrink bands that are very strong and provide a uniform grip around the hose. Also, they do not damage the rubber of softer hoses such as silicone.

Of course you will need to have one removable clamp now and then so the hard line can be disassembled but I'd recommend using a T-bolt clamp for that.

Regards, Neil Tucson, AZ

Neil,

The system that you refer to works very well but I'm just wondering if you realize that H has built cars which have logged thousands and thousands of grueling miles under actual race conditions (including finishing the 24 hrs of LeMans!!!!)?? I think he might know what works and what doesn't .

Ron

Neil

Supporter

Neil,

The system that you refer to works very well but I'm just wondering if you realize that H has built cars which have logged thousands and thousands of grueling miles under actual race conditions (including finishing the 24 hrs of LeMans!!!!)?? I think he might know what works and what doesn't .

Ron

I was not questioning anyone's resume, just making a suggestion. New, useful stuff comes along now and then and not everyone may be aware of them.

Regards, Neil Tucson, AZ

A nice little Carbon exhaust trim really finishes things off

Im working on trying to get the interior trimmed out with this mid window closeout panel

So onto the door cards, its something I've been working on for a while making patterns, molds and parts. Now onto the instal, its three pieces per door, consisting of the pocket, the main card and a trim ring, as of now all made out of GRP.

First up was to instal an internal door release lever, which was made out of a bicycle brake lever welded to a short piece of angle and bolted to the main part of the door. I wanted something that could stay with the door from now on with or without the door cards in place.

Next is to fit the pocket over the lever and instal the oval pull handle for closing the door. The pull handle is mounted with two 6mm rivnuts in the door inner skin and also holds the pocket in place, remarkably stout.

The main card then fixes over the pocket holding it all together with another five 4mm button head bolts.

Over the joint goes the trim ring giving it a fairly reasonable OEM look.

Later ill add the electric window switches to the pocket area

First up was to instal an internal door release lever, which was made out of a bicycle brake lever welded to a short piece of angle and bolted to the main part of the door. I wanted something that could stay with the door from now on with or without the door cards in place.

Next is to fit the pocket over the lever and instal the oval pull handle for closing the door. The pull handle is mounted with two 6mm rivnuts in the door inner skin and also holds the pocket in place, remarkably stout.

The main card then fixes over the pocket holding it all together with another five 4mm button head bolts.

Over the joint goes the trim ring giving it a fairly reasonable OEM look.

Later ill add the electric window switches to the pocket area

H looking good is the door card a piece off the mold and the trim ring oem

Yes in this picture, the trim ring is OEM part from my car, I have made these parts in GRP also, but in black they don't show up for the photo.

H anymore progress on Jared's car just curious

Moving on to B pillar caps and cill steps.

Joel K

Supporter

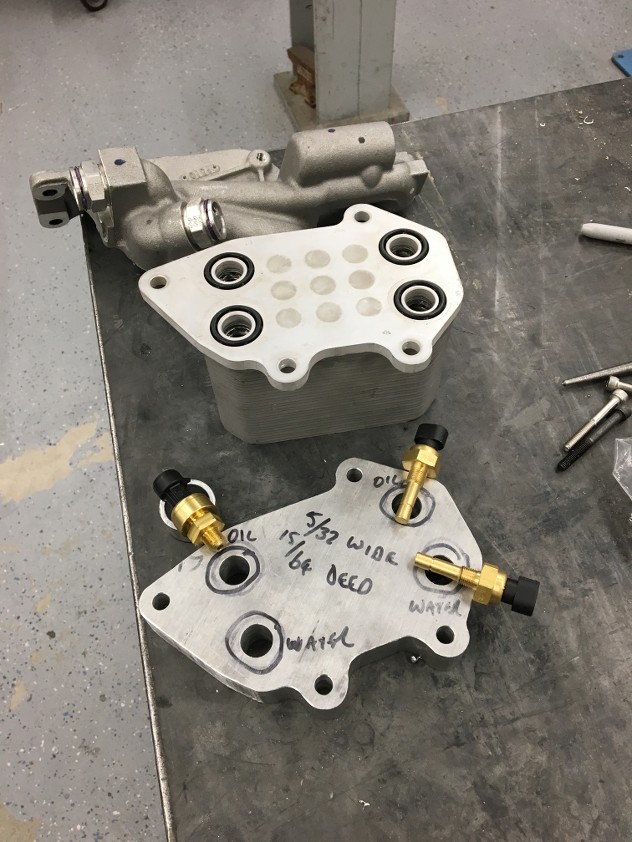

The LT4 is not user friendly when it comes to installing extra sensors for the gauges, there just aren't places to put them, so Ive removed the intercooler heat exchanger and I'm working on this sandwich plate into which I can plug the oil pressure and temp sender and water temp sender.

Andy, thanks for posting all these build details. Very clever way of mounting the senders. I am planning on using an LT4 in my upcoming SLC Build. How did you seal the top of the sandwich plate? Did you make a gasket or insert rubber seals like in the bottom part of the unit? Also, how far in do the temp sensors go, based on the way they are laid out in the pic above it looks like they go all the way through. Just wondering if that would impede the flow of the water and the oil through the cooler?

Hi Joel, Yes i cut O ring grooves on one side so as to replicate the cooler. as for the sensor depth I used 1/4 to 1/8 adapters into the plate which puled them back out of the fluid passages the hole drilled for the 1/4 pipe tap blows sufficient fluid around the sensor tip.Andy, thanks for posting all these build details. Very clever way of mounting the senders. I am planning on using an LT4 in my upcoming SLC Build. How did you seal the top of the sandwich plate? Did you make a gasket or insert rubber seals like in the bottom part of the unit? Also, how far in do the temp sensors go, based on the way they are laid out in the pic above it looks like they go all the way through. Just wondering if that would impede the flow of the water and the oil through the cooler?

Joel K

Supporter

Hi Joel, Yes i cut O ring grooves on one side so as to replicate the cooler. as for the sensor depth I used 1/4 to 1/8 adapters into the plate which puled them back out of the fluid passages the hole drilled for the 1/4 pipe tap blows sufficient fluid around the sensor tip.

Thanks Andy, appreciate your help.

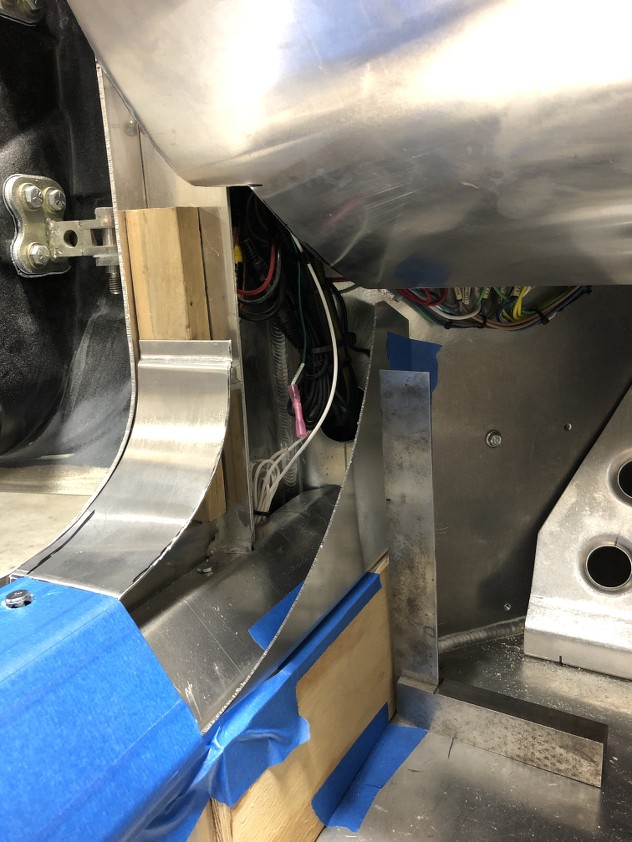

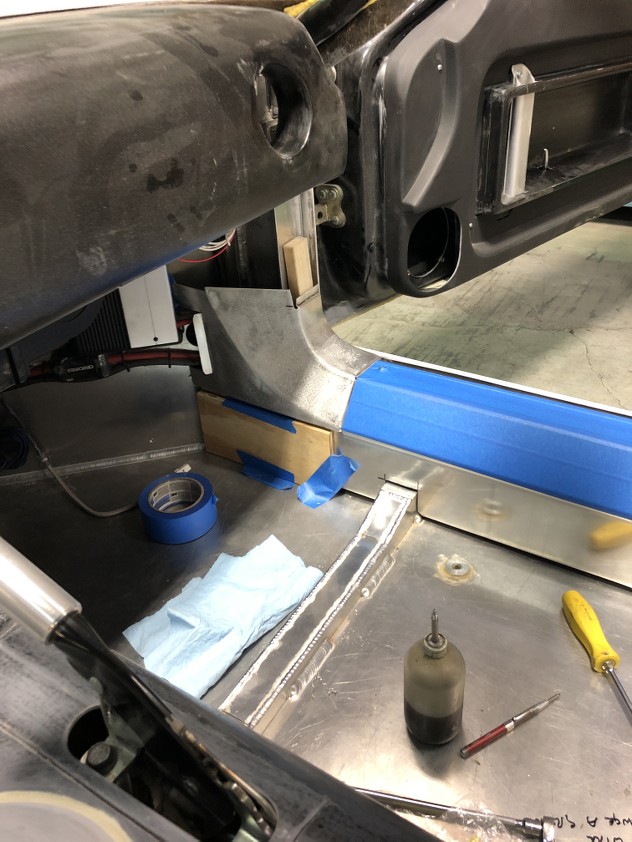

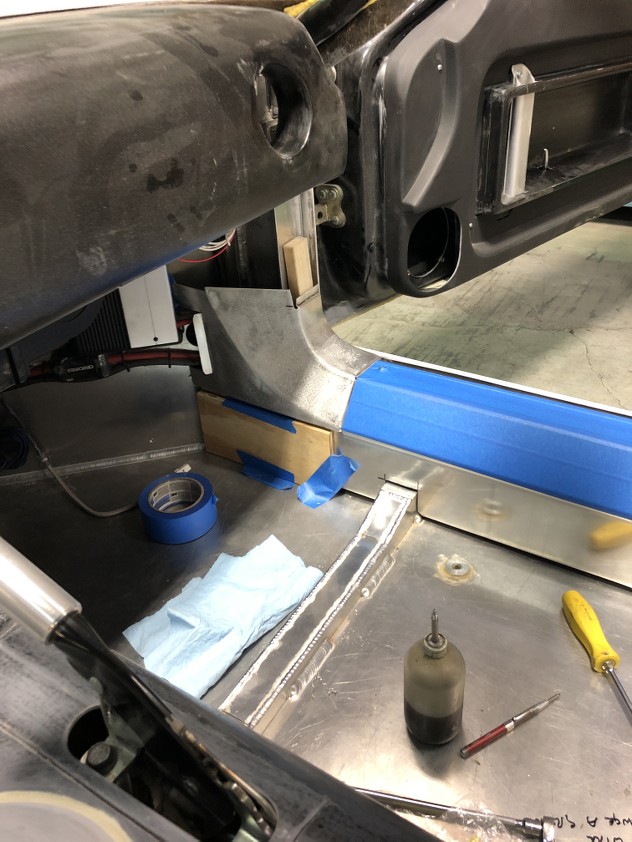

The interior trim panels are coming along nicely, Im going to work my way around the A & B pillars then finish the base speaker cover last. all the other surfaces will be just sound deadening and carpet. Im not yet sure what Jared wants as a finish to the aluminum covers but Im thinking the rear window cover will get carpet and the dash and aluminum will probably be covered in leather.

This A pillar cap had me really thinking this morning, it took a while for sure to work out how to tie the dash and cill step together.

It ended up out of three pieces and some compound curves, Jared suggested that it looked easy! not really sure why he's paying me to do this if thats the case

After this was in place it was just a matter of bringing the corner of the under dash down to meet the cap.

It wasn't until I'd finished that I remembered about the recess in the door card, lining up with the dash

I guess I got lucky this time

Friday I made up the other side A pillar cap. Now I'm looking to create the glove box. I had to go back and wade through all my build photos to try and find one with enough of an image to remind me how I did the first one, It really dose not matter how many photos you think you took, you never seem to have the right one

This bracket is from where the glove box will hinge and where the two pieces of lower dash either side of the glove box will mount.

This bracket is from where the glove box will hinge and where the two pieces of lower dash either side of the glove box will mount.

Similar threads

- Replies

- 7

- Views

- 3K

- Replies

- 6

- Views

- 422